- +86-755-88868631/27659298

- aglare@aglare.com

- +86-755-88868631/27659298

- aglare@aglare.com

New equipment LED lamp bead splitter and wire bonding machine introduced by our company!

2019-06-18 11:05:59

Recently, the new equipment LED lamp bead splitter and wire bonding machine introduced by our company have been officially put into use.

1. The splitter, the full name of the LED splitter, is a necessary device for the light-emitting diode (also known as LED) in the production process. It is used to classify and filter the LED according to the wavelength (color), light intensity, current and voltage of the emitted light.

It consists of three main parts:

(1) High-speed optical spectrometer;

(2), electric parameter measuring instrument;

(3) Mechanical transmission system; the most important and key part is the high-speed optical spectrometer. Since the spectrometer requires a sorting speed of more than 10,000 LEDs per hour, the detection and data processing speed of the optical spectrometer is very high.

2. Wire bonding machines are mainly used in high-power devices: light-emitting diodes (LEDs), laser tubes (lasers), small and medium-sized power transistors, integrated circuits and internal wiring of some special semiconductor devices.

Wire bonding machine works:

(1). The machine is used to realize the surface welding of different media. It is a physical change process. First, the first end of the gold wire must be processed to form a spherical shape (the machine uses a negative electron high-pressure ball), and the welded metal surface is pre-prepared. Heat treatment; then the gold ball is plastically deformed on the metal welding surface under the action of time and pressure, so that the two media reach a reliable contact and vibrate by ultrasonic vibration, the role of atomic affinity between the two metal atoms The metal bond is formed underneath to realize the welding of the gold wire lead. The Nitto gold wire ball bonding is superior to the silicon aluminum wire welding in electrical performance and environmental application, but the welding range of the precious metal must be heated, and the application range is relatively narrow. .

(2). The ultrasonic wave (generally 40~140KHz) generated by the interaction between the ultrasonic source and the transducer, the energy is concentrated at the tip of the porcelain tip through the horn, and the lead wire (gold wire or aluminum wire) is driven by the porcelain mouth. Frequency vibration, rubbing against the surface of the metal to be welded, the surface oxide layer is cracked, and plastic deformation occurs, and finally a firm metal bond is formed on the welded surface.

The LED lamp bead splitter and wire bonding machine introduced by Shenzhen Aglare Lighting have precise and efficient features, improve the utilization of electric energy, and have taken a solid step in response to the call for energy saving in the motherland. Compared with traditional machines, it has the advantages of high productivity, precise conditions and defective product alarms, ensuring reliable quality of manufactured products. Greatly shorten product cycle time and strongly guarantee the delivery cycle.

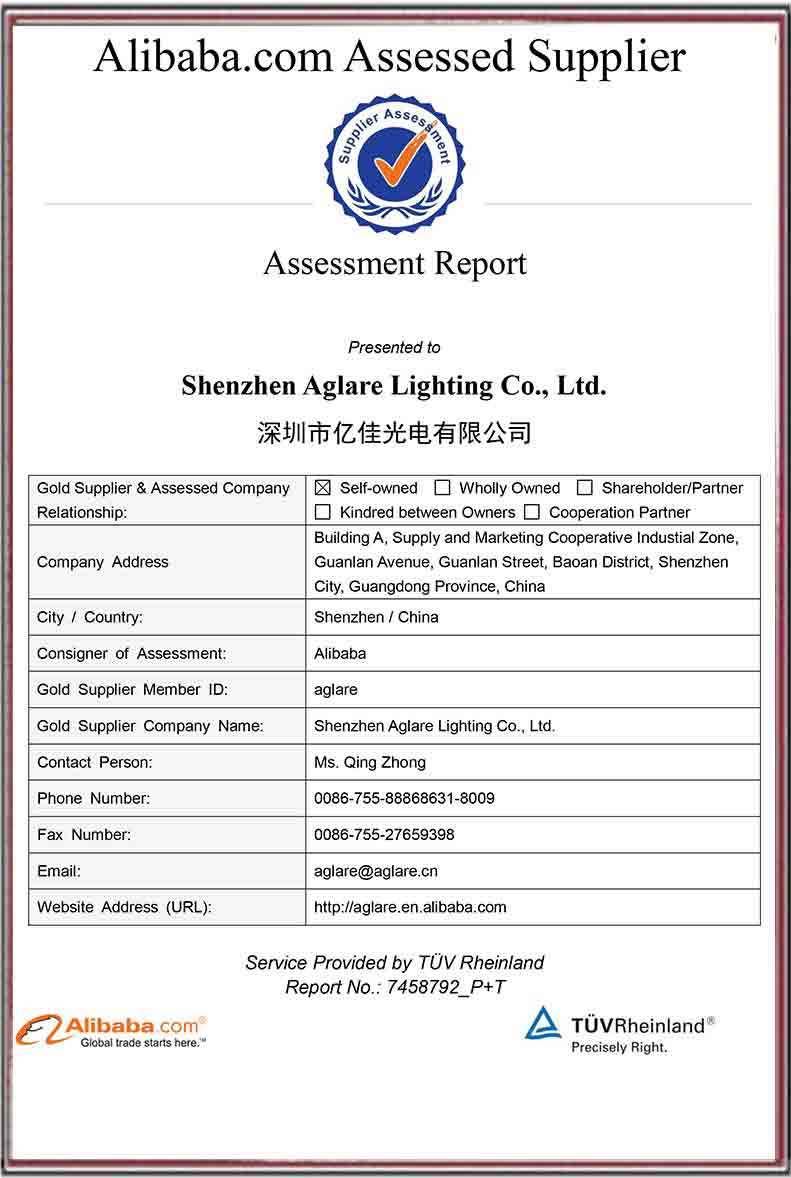

Certification

Aglare Lighting Co., Ltd. was established on January 25th, 2005, which is a LED manufacturer for LED flood Light, LED High Bay Light, UFO LED High Bay light and other outdoor lighting products.

.jpg)

.jpg)

.jpg)